Version Details

MecaLug is a Padeye or Lifting Lug Calculation Software package that is used to perform padeye or lifting lug calculations as well as analyze loads acting on padeyes or lifting lugs for a structure or piece of equipment. Several different styles of padeyes or lifting lugs are offered giving the user multiple options in selecting an appropriate lifting lug. There are also several different configurations in the MecLug Software for different equipment and structures. The lifting lug software even has templates for lifting a stack or cylindrical vessel from horizontal to vertical, using either lifting lugs or lifting trunnions. For this special type of lifting of stacks, the lifting lug software considers the multiple angles as the structure rotates from horizontal to vertical in order to find the worst angle on the lifting lugs/trunnions and tailing lug.

MecaLug Standard

MecaLug Standard version is the least expensive version of the software that allows the user to perform Padeye / lifting lug calculations per ASME BTM-1 “Design of Below-the-Hook Lifting Devices”. Engineers often design structures and equipment for extreme wind, seismic and other loading that may never occur; however, in the case of a lifting lug those extreme loads may very well be experienced at the beginning of the equipment life cycle, not in 20+ years down the road. The failure of a lifting lug could very likely put human life in danger in the event of a failure. The lifting lug software allows the user to quickly and accurately analyze Padeye / lifting lugs for a variety of loads.

MecaLug Pro

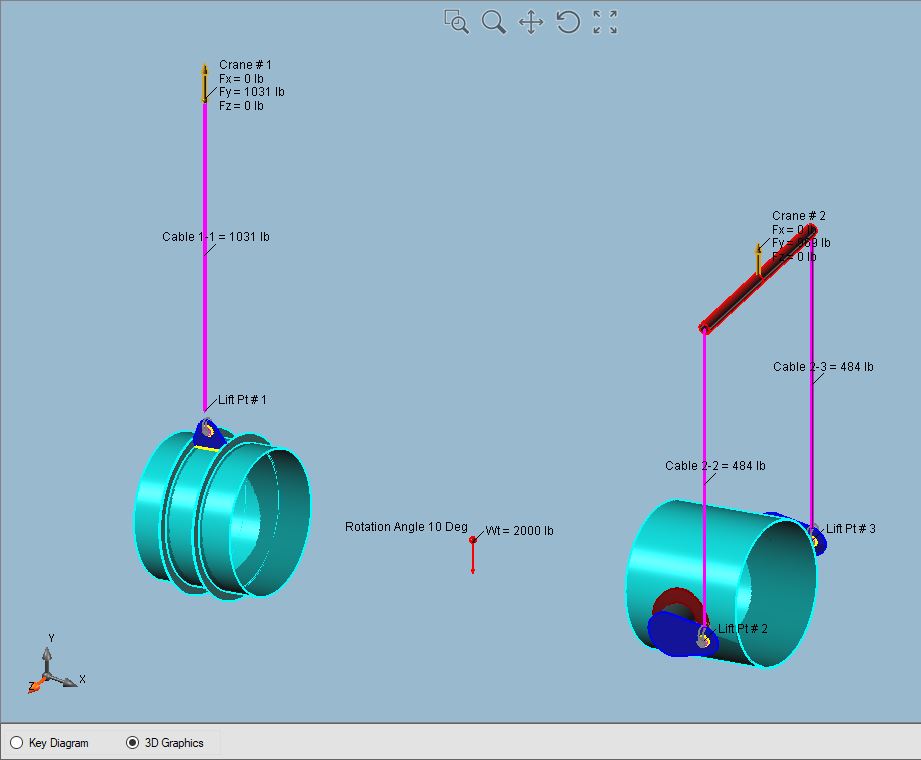

MecaLug Pro version offers the same features of the standard version of the lifting lug software of analyzing a single lug or trunnion, but MecaLug Pro also has the added benefit of being able to apply those lugs to a lifting system and analyze what loads would be seen by the crane, cable, and lugs. This Pro feature of the MecaLug allows the designer to consider lifting a piece of equipment or structure, and have the software determine the loads acting on each individual lug. The analysis of each lug is then performed by the lifting lug software. The Pro features make MecaLug an all-in-one lifting lug software.

Lifting Lug/Padeye Calculation Software

Both the Standard and Pro version of MecaLug will allow the user to perform lifting lug calculations for a single Padeye / lifting lug. There are a variety of different Padeye / lug configurations that can be chosen to suit the specific needs. There are countless different lifting lug configurations used by companies, and so it’s not feasible to include every possibility. We have focused on the most common types of lugs that are used in the industry and those have been included in the lifting lug software.

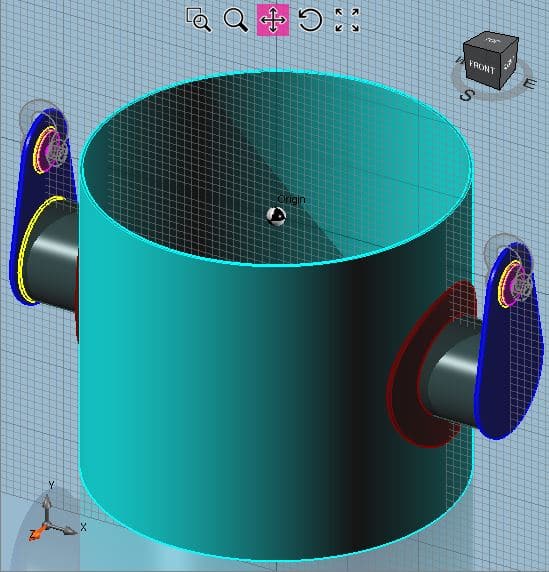

In the case of lugs attached to cylindrical shells, the local stresses are a concern from the lug acting on the cylindrical shell. MecaLug adopts the use of ring analysis as well as local stress per WRC 537 (also known as WRC 107) to calculate the local stresses on the cylindrical shell. This is especially important when analyzing lifting trunnions on cylindrical shells (shown to left), such as stacks or vessels, so that the local stress of the trunnion acting on the shell is considered.

As the data for the lifting lug or system is entered, a 3-dimensional representation is shown on the screen based upon the user entered parameters. This gives a quick check of all values entered to make sure they look correct.

The design of a single guyed stack usually saves enough time to recover the cost of the software.

Steel Stack Design Codes

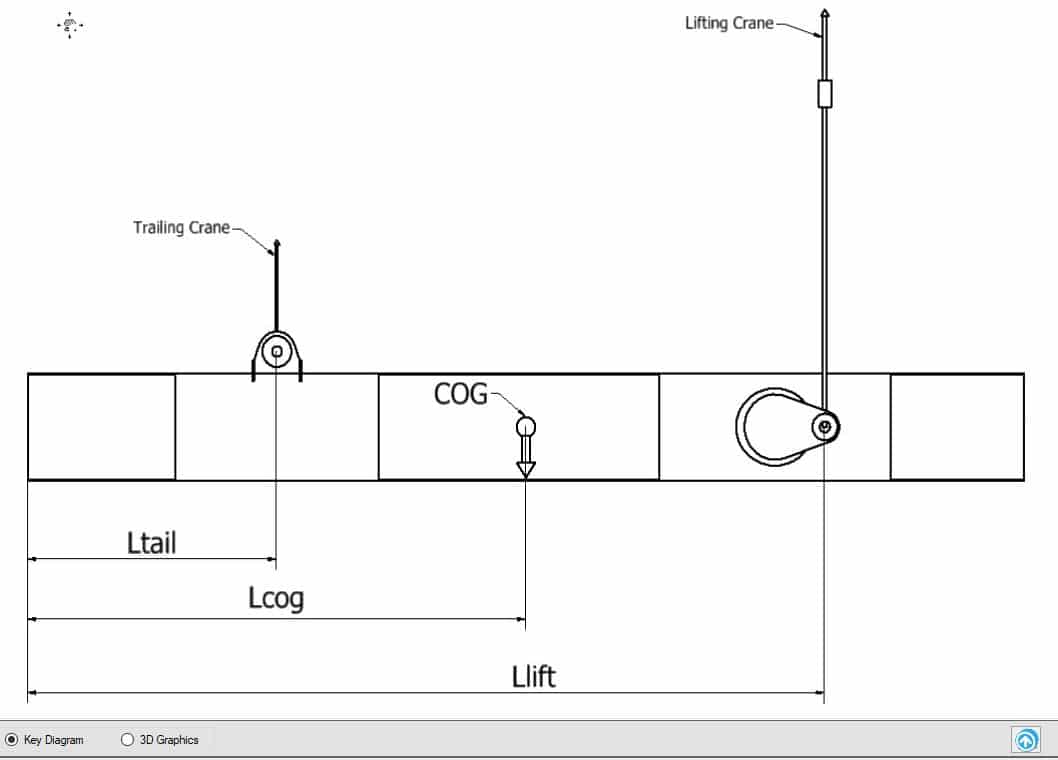

There are unique problems that occur when a stack, vessel, or tower is lifted. The structures usually start in the horizontal position and then they are rotated 90 degrees to the vertical position. MecaLug Pro has provisions to analyze the structure at each increment of the lift, and calculate the loads acting on the lifting lugs, trunnions, or tailing lugs at each of these increments. We offer another software package called MecaStack, and this software will check the bending stress in the stack due to lifting, but it doesn’t check the actual lifting lugs/trunnions or tailing lug. MecaLug picks up where MecaStack leaves off in that it will also check the actual lugs for the loads during each step of the lifting process.

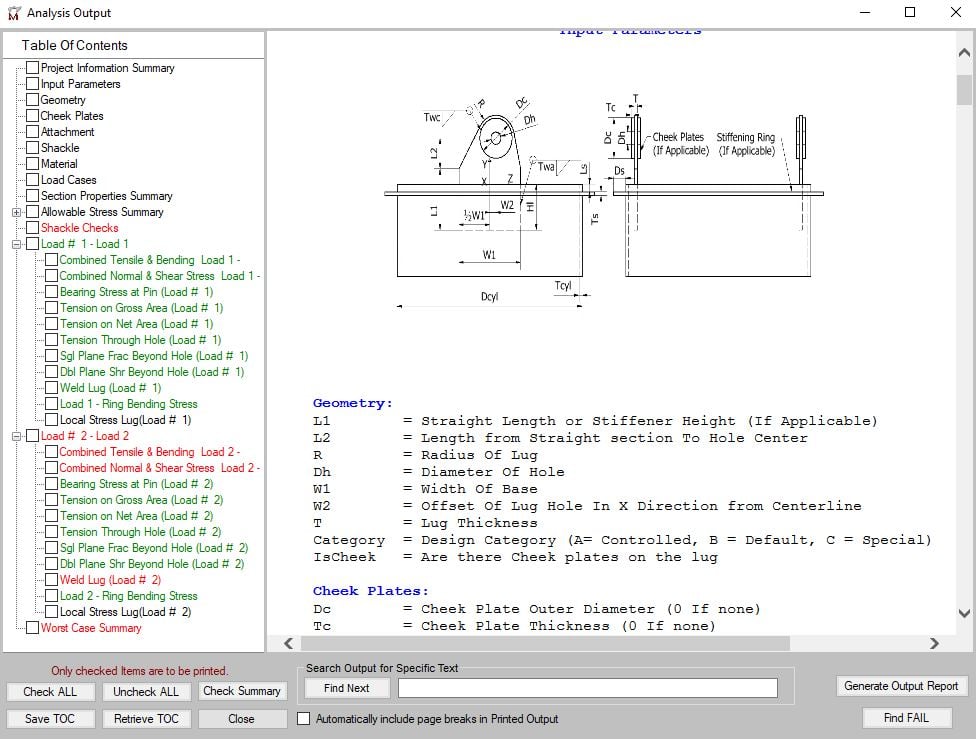

When modelling the lifting lug the user will need to specify the following:

- Lug Geometry

- Cheek Plate Dimensions (If applicable)

- Attachment dimensions (i.e. cylindrical shell, beam, etc..)

- Shackle selection (Checks clearances and capacities)

- Material properties

- Loads acting in the X, Y and Z direction on the lug (Multiple load cases may be entered)

When modelling the lifting system the user will need to specify the following:

- Lifting System Configuration

- The lugs being used and orientation (if necessary)

- Configuration dimensions

- Location of Center of Gravity for system

- Total Lifting Weight

- Vertical height from lug to crane

After the data is entered, the analysis can then be performed. The user can quickly determine Pass vs Fail by using our simple system where Green is Passing and Red is Failing. You can quickly survey the output and determine the problematic areas. After the design is final, you can then pick and choose which information will be used in the final report.

For a single lug analysis, this will contain a complete analysis of the lug per ASME BTH-1, considering each of the load cases entered by the user. MecaLug is a complete lifting lug calculations software package.

For the lifting system, a complete analysis of the loads in each cable, at each crane point, and acting on the lugs.

MecaLug Software Version Comparison

| Feature | Standard Version | Pro Version |

|---|---|---|

| Single User Pricing | $234 | $378 |

| Network Pricing | $468 | $756 |

| Single Lifting Lug Analysis | ||

| Lug Shackle Checks | ||

| ASME BTH-1 Calculations | ||

| Lifting Trunnion Analysis | ||

| Complete Lifting System | ||

| Calculate Crane Reactions | ||

| Calculate Cable Loads |

Fill out the “MecaLug Version Wizard” (found below) to receive an email for what version of the software would best meet your needs based on the parameters you entered.

MecaLug Version Wizard

Frequently Asked Questions

Can I get a fully functioning demo to try out the software?

We offer a limited demo, but we do not offer a fully functioning demo. The demo will give you a good feel for how the lifting lug calculation software will function.

How quickly can I begin using the software?

Our order process is completely automated. If you purchase online, you will automatically receive an email with instructions on downloading and activating the software. This information also appears on the last page of the order process. You will be using the software in minutes after purchase.

How do I renew the lease on my software to get the Early Pricing?

Thirty (30) days prior the the expiration date on your lease, you should receive an email reminder. In addition, any time you open the software within that 30 day period prior to expiration, you will get a warning in the software that it’s about to expire. To renew pricing and get the best pricing, go to the “Customer Portal” option at the top of this page. Log into our customer portal, and then go to “Renewals and Upgrades”. Here you should see the [Early] renewal option. Place the order online, and the expiration date will automatically be extended by one (1) year.

REFUND POLICY

Refunds must occur within 72 hours of purchase. The customer will need to email [email protected] with their refund request with proof of purchase attached.

Discover Innovative Engineering Solutions for Your Projects!

Explore how Meca Enterprises can elevate your engineering endeavors with cutting-edge software, expert consulting, and reliable solutions. From wind load calculations to stack design and more, our comprehensive services and products are tailored to meet your unique needs. Contact us to take the next step towards engineering excellence with Meca Enterprises!

-

Call Meca Enterprises at 918-258-2913

-

Visit Meca Enterprises in Broken Arrow

-

Email Meca Enterprises Support