ENGINEERING SERVICES

Meca Enterprises specializes in steel stack design, as well as the design of other types of process equipment, and provides structural analysis for air cooled heat exchangers.

Thanks to today’s technology, most of our communication and design can be done completely via phone and email. We send all designs electronically in a PDF file, which allows immediate transfer of information.

For any inquiries/quotes about consultation or structural design work, please email us at [email protected]

Professional Affiliations:

- Member of ASME STS-1

- Committee for Steel Stack Design Standard

- Lead of Dynamic Subcommittee Design

Registered PE in the following states:

- California

- Louisiana

- New Mexico

- North Dakota

- Oklahoma

- Oregon

- Texas

- Connection with third party for other states needed

Registered PE in the following Provinces:

- Alberta, Canada

- British Columbia, Canada

- Ontario, Canada

- Saskatchewan, Canada

Self Supported Stack Design

Meca has designed many different types of self supported steel stacks, ranging in height from 6 m (20ft) to 100 m (328 ft.). Some special design considerations we experienced have included:

- Single Piece Lift of Stack

- Special Breech Openings

- “Piggy Back” Stacks

- Vibration Design

- Retrofit of Existing Stacks

Guy Wire Supported Stack Design

There are very few companies that perform the design of guy wire supported stacks. Meca has designed many guy supported stacks ranging from 15 m (50 ft.) to 167 m (550 ft.) in height. We can save you considerable time and money due to our experience in the area of guyed stack design and with our in-house designed MecaStack software. We have performed the following types of special designs:

- Low Temperature Design (Ambient and Cryogenic)

- Unique Guy Arrangements

- Tandem and Piggy Back Stacks

- Single Piece Lift of Stack (sometimes done from multiple lift points)

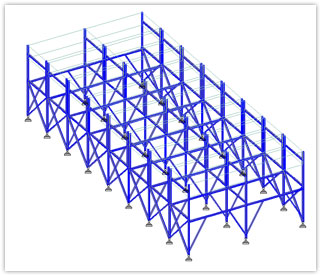

Derrick Supported Stack Design

Extensive experience designing derrick supported stacks:

- 3 Sided or 4 Sided

- Pipe Members

- Flat Faced

- Demountable

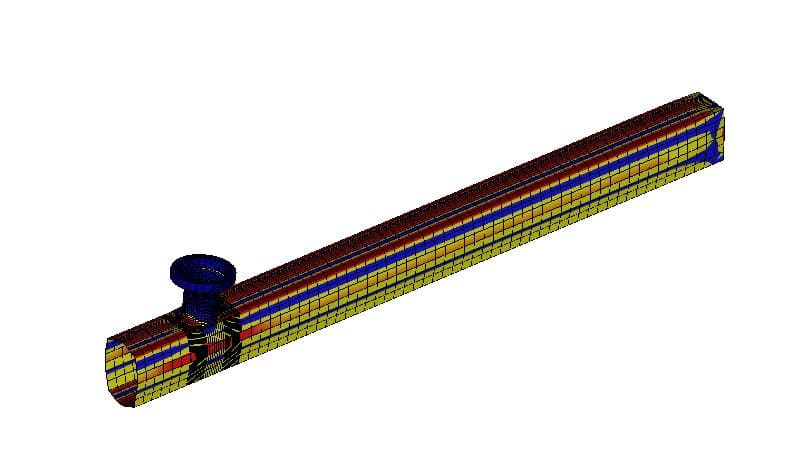

Finite Element Analysis

Finite element analysis does not always have to be expensive. We encounter certain types of problems repeatedly involving stacks, piping, pressure vessels, etc.. Therefore, we have become very adept at building certain geometries for analysis very quickly to provide a cost effective solution.

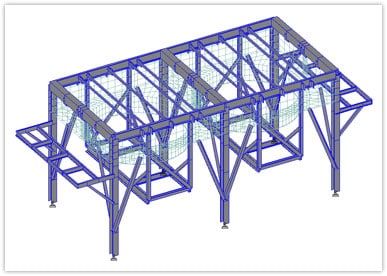

Air Cooled Heat Exchanger Structural Analysis

Meca has years of experience verifying the structural integrity for air coolers of various types and designs. We also have experience in the verification of box headers and FEA of nozzles.