DAMPING PADS

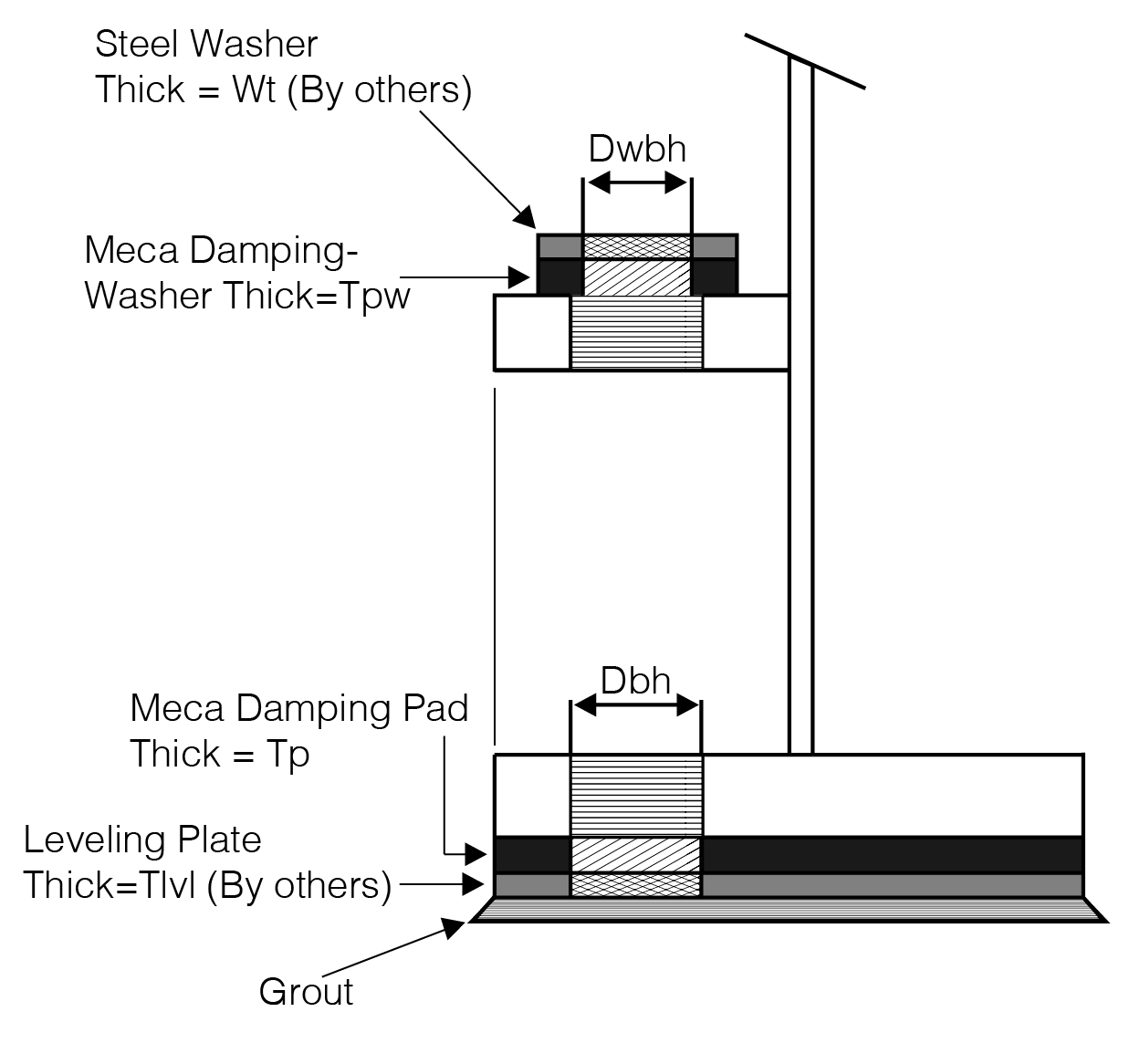

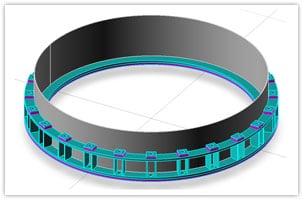

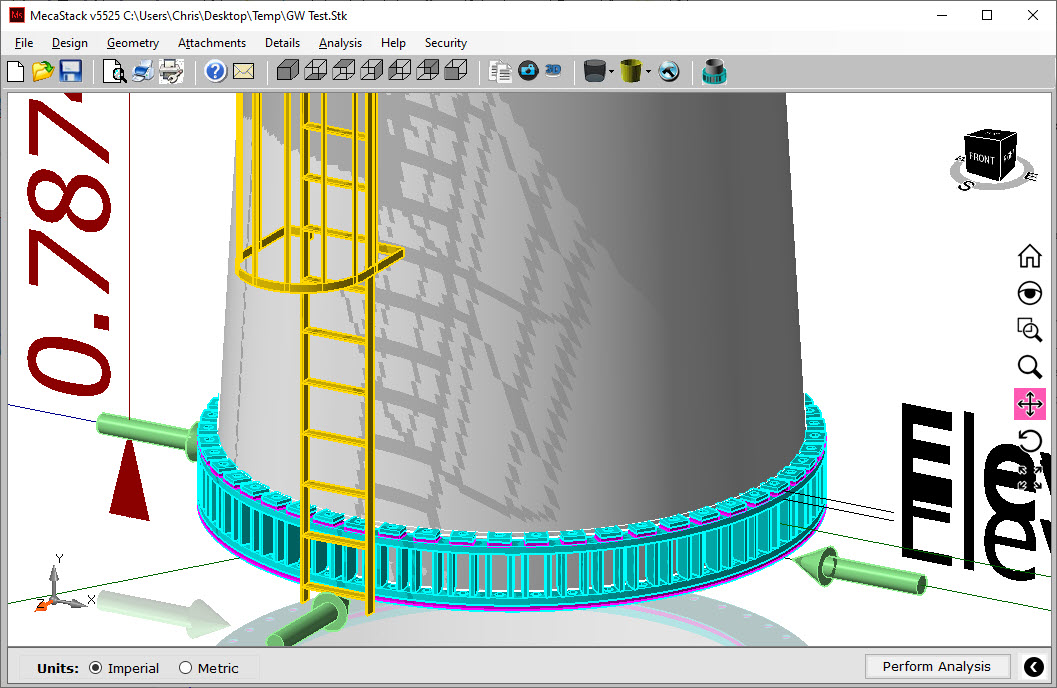

Damping pads are installed on the bottom of a baseplate, so that they are acting in compression. In addition, damping tension is installed on the top side of the baseplate, so that when the bolt is in tension the damping washer is compressed. This damping pad/washer system serves to increase the damping of the stack structure, and suppress wind induced vibration on the stack. The addition of the damping pad does slightly increase the flexibility of the base, which can result in slightly higher lateral deflections when the stack is subjected to along wind loadings. Usually this increase is minimal, but Meca can estimate the additional deflection for a specific stack.

Advantages

Does not increase wind loads

Impervious to most oils and solvents

Not frequency dependent and works for all modes of vibration

Disadvantages

Can only withstand temperatures up to 200 F (93 C)

Difficult to retrofit existing stacks

Slight increase in lateral deflection

Does not provide enough damping for every stack

I have a vibration problem, what’s next?

If you are unsure that a damping pad is the right option to reduce the effects of vortex shedding (wind induced vibrations) on your stack, then click on our “Vortex Shedding Solution Wizard” to receive an email about our general recommendation based on your parameters entered.

Vortex Shedding Solution Wizard

FREQUENTLY ASKED QUESTIONS:

How do damping pads work?

It has been well documented that elastic foundations provide more structural damping than rigid foundations. The damping pads introduce elasticity into the foundation which increases the inherent structural damping. This results in reduced vibration amplitudes. In fact damping pads are listed in ASME-STS -1 as an acceptable means to dampen a stack.

How much damping can be achieved?

Field tests have been performed which indicate that critical damping values of up to 0.001 to 0.03 have been achieved. Meca will estimate the damping that is to be expected on a specific stack.

Will this cause the stack to see larger lateral deflections due to along wind loads?

The damping pads do introduce some elasticity into the base, but they are also very stiff. There will be minimal impact on the lateral deflection due to along wind loads.

Do the pads hold up over time?

These pads have been in service for up to 30 years, with no reported problems.

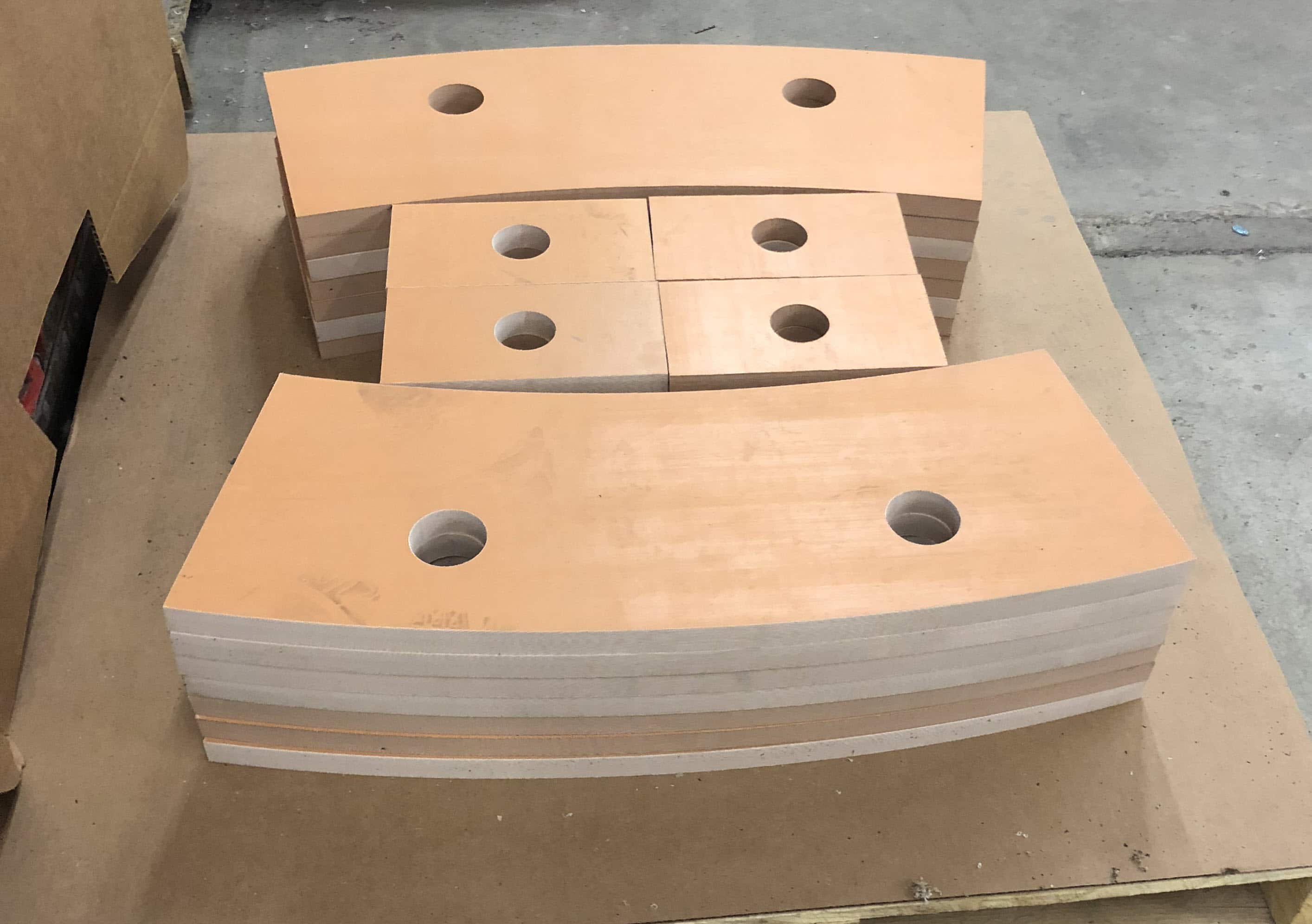

Can pads be used on existing stacks?

It is possible to use pads on existing stacks, but the stack must be raised in order to insert a pad under the baseplate. Typically pads are 1″ thick, so it must also be considered that stack connections will be raised approximately 1″.