TUNED MASS DAMPERS

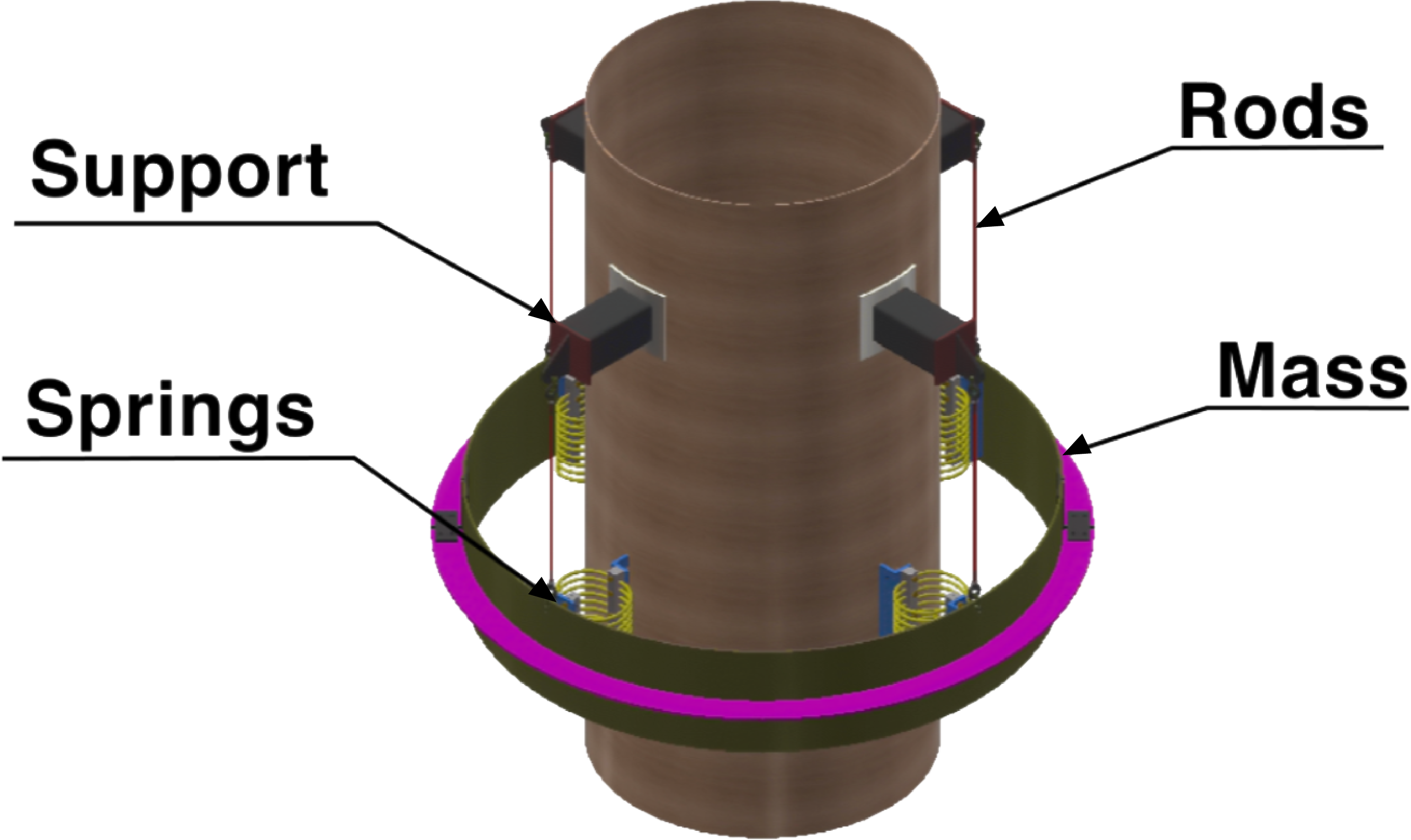

A Tuned Mass Damper (TMD) is device that is added to the top portion of the stack that increases the damping of the stack, which will suppress wind induced vibration. The device consists of some addition of mass and springs, that is tuned to the natural frequency of the structure. The TMD can take different forms, but the most common style is to have a cylinder that acts as a mass, which is larger than the diameter of the stack. The mass is supported by some pendulum rods, which suspend the mass. Between the mass and stack are springs. The entire assembly is designed to a specific natural frequency of the structure, so that it will provide damping to suppress any vibrations.

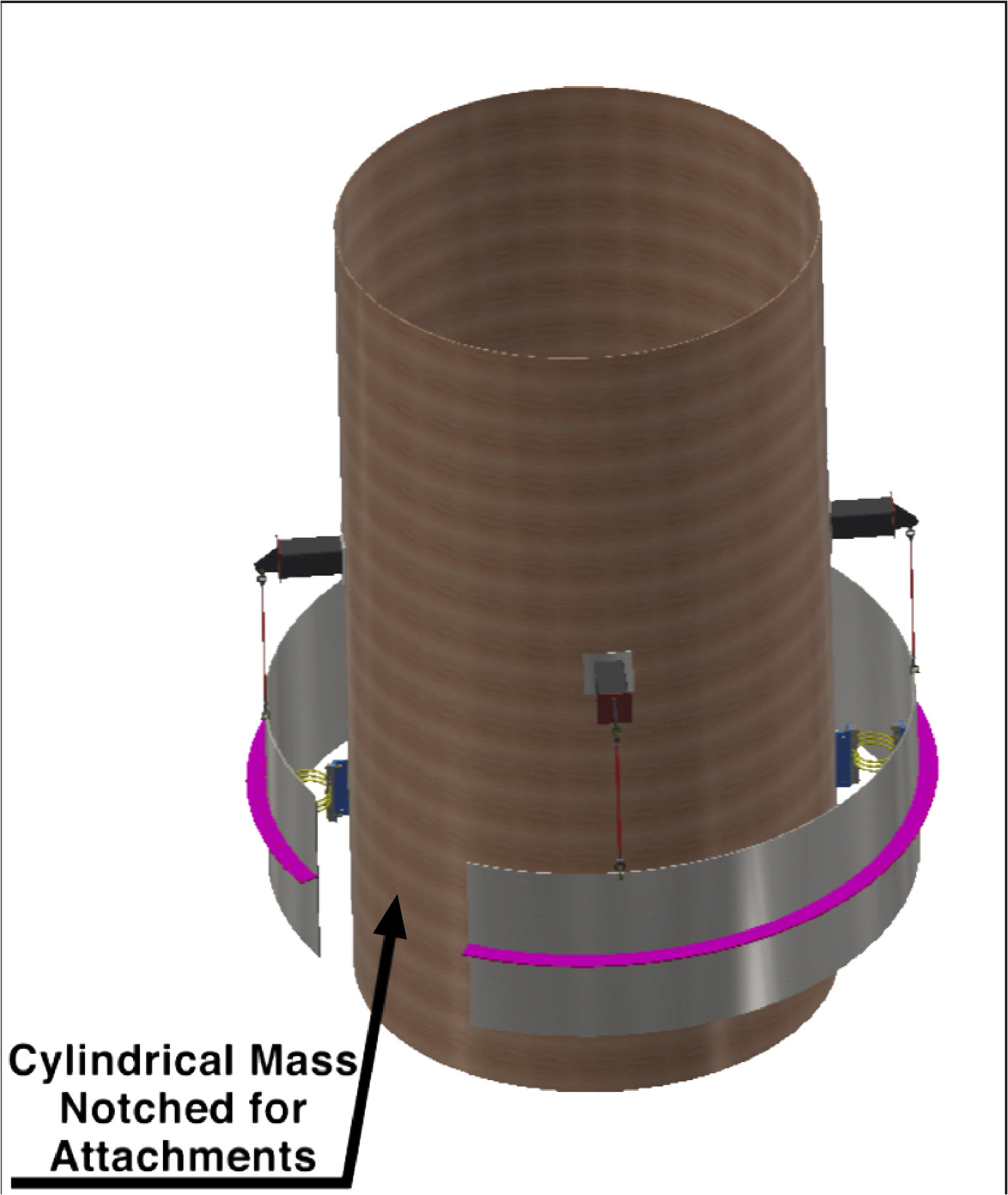

The Tuned Mass Damper (TMD) typically is near the top of the stack and it works best on stacks and chimneys without a lot of external attachments. The mass can be notched to accommodate an external attachment such as a caged ladder.

For more technical info about TMDs, check out our article: Tune Up your Next Stack

Advantages

Can Provide High Damping

Relatively low weight and wind drag

Can visually see TMD working

Proven design with decades of service

Disadvantages

Must be near the top of the stack

Less economical on short stacks

Less desirable with lots of attachments; however, we can notch the mass to accommodate a ladder or some small attachments

I have a vibration problem, what’s next?

If you are unsure that a tuned mass damper is the right option to reduce the effects of vortex shedding (wind induced vibrations) on your stack, then click on our “Vortex Shedding Solution Wizard” to receive an email about our general recommendation based on your parameters entered.

Vortex Shedding Solution Wizard

FREQUENTLY ASKED QUESTIONS:

Does the damper have to be at the top of the stack?

The damper is most effective where the deflection of the stack due to vibration is maximum. For the first mode of vibration, that would typically be at the top of a stack. The TMD can be placed lower than the top, but the trade-off is that the mass of the TMD must increase to compensate for being at a less desirable elevation.

Is the damper mass always 360° in circumference?

Ideally the mass does wrap 360° around the stack; however, there are many instances where the mass cannot be wrapped 360° around the stack due to Ladders, Piping or other attachments on the stack. In some instances the mass ring is broken, to allow the obstruction to pass through (i.e. a ladder). In other instances where there are multiple obstructions, a special TMD can be designed to utilize independent masses which do not require a continuous ring.

What inspection is required on a TMD?

A TMD can usually be observed from grade using a pair of binoculars. An obvious failure, such as a spring or Pendula failing, would probably be visible from grade with binoculars. If it is feasible, we would recommend performing a visual inspection of the TMD once every 1 to 2 years from a close proximity, but if that is not realistic then using binoculars will be adequate.