TUNED LIQUID DAMPERS

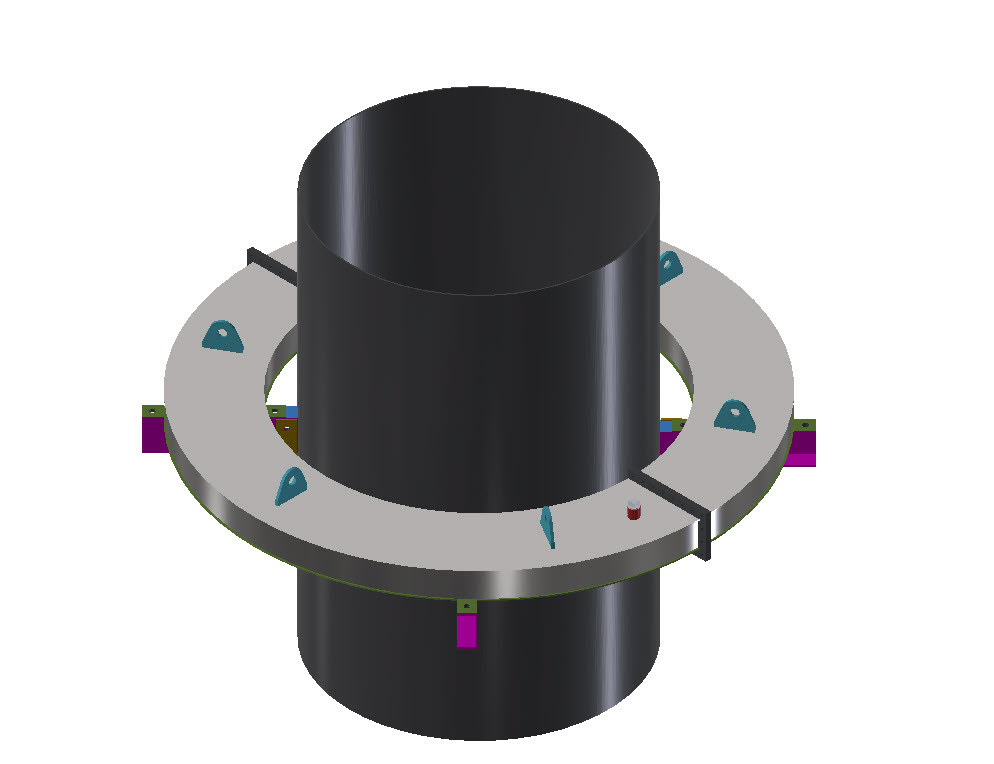

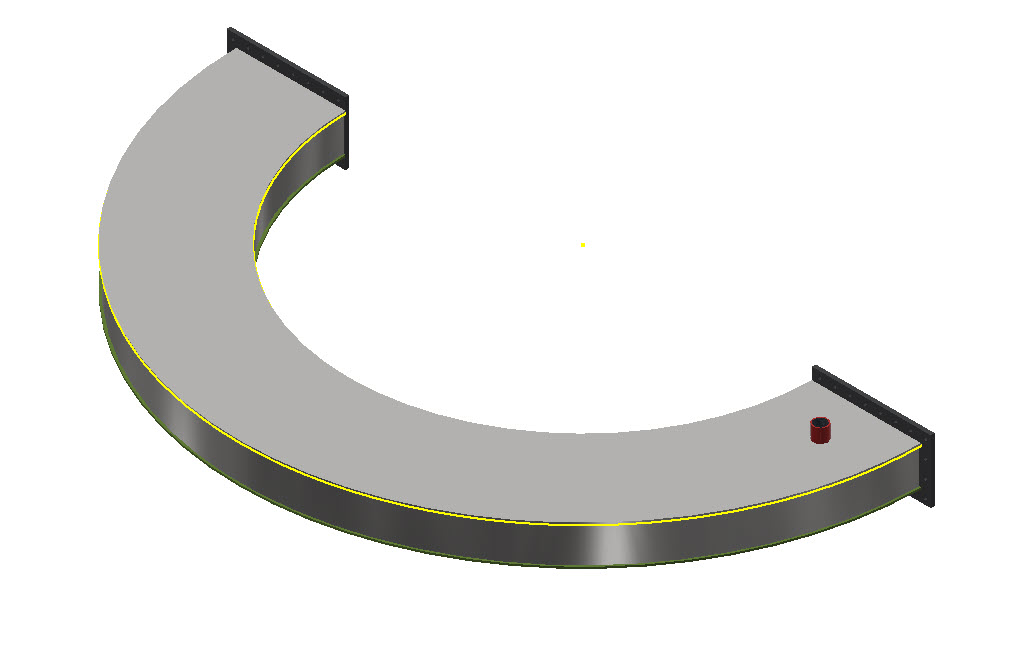

A Tuned Liquid Damper (TLD) is an annular box, which is partially filled with a water/glycol mixture. The box is specially designed to maximize the damping effectiveness of the fluid that is contained by the damper. This style of damper is unique in that it can also be used as a platform with the addition of handrails. The damper has no moving parts, the damping is provided by the sloshing of the liquid that is internal.

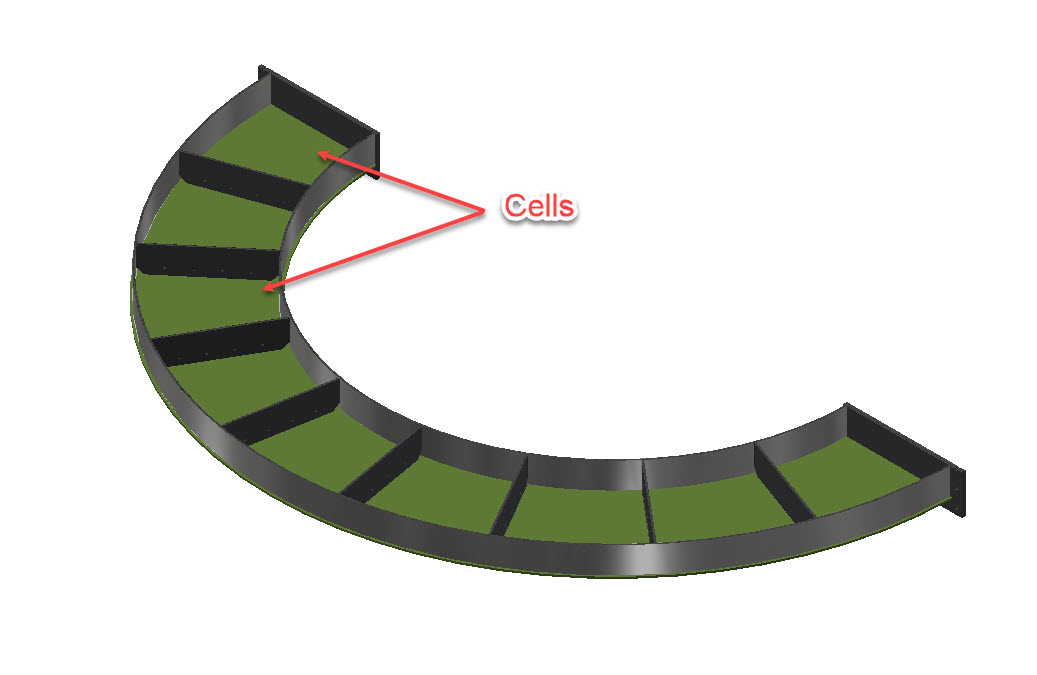

The Tuned Liquid Damper (TLD) is comprised of one (1) or more chamber, and this chamber is composed of multiple individual cells. Each cell is partially filled with a mixture of fluid, normally a mixture of water and ethylene glycol in order to prevent the fluid from freezing.

TLD Damper in the shop…

…and on the stack

TLD Damper in the shop…

…and on the stack

TLD Damper in the shop…

…and on the stack

Advantages

Can Design for Multiple Modes

No Moving Parts

Relatively low weight and wind drag

Can also serve as a Platform

Disadvantages

Needs to be near the top of the stack

Difficult with multiple attachments

Can’t see liquid from grade

I think I have a vibration problem, what’s next?

If you are unsure that a tuned liquid damper is the right option to reduce the effects of vortex shedding (wind induced vibrations) on your stack, then click on our “Vortex Shedding Solution Wizard” to receive an email about our general recommendation based on your parameters entered.

Vortex Shedding Solution Wizard

FREQUENTLY ASKED QUESTIONS:

Will the water freeze?

A mixture of water and antifreeze (Ethylene Glycol) is recommended with each design to prevent freezing.

Is the Damper shipped full of liquid?

Typically the damper is shipped empty, and the liquid is added at the job site per our specifications.

How will I know if the damper is leaking fluid?

During fabrication a pressure test is performed to ensure that the damper is water tight at time of shipment. In real world conditions the damper will not be exposed to pressure, and so leaking is unlikely. There are a couple of ways to verify that the damper has liquid 1) If the stack is vibrating, 2) Open the damper filler cap and look inside damper.

Will the fluid cause corrosion?

Some corrosion will be experienced, as is expected with all carbon steel; however, only modest corrosion rates have been witnessed on damper installations. The damper is a closed system, no air is infiltrating the inside chamber of the damper. It would be similar to a radiator on a car, since there is a closed system then corrosion is not expected to be significant.

What damping ratio should I expect with a damper?

Damping ratios up to 0.035 and up can be achieved, with the average being about 0.02. If needed, the Damper can be designed to provide much greater damping. The damper size and effective additional Damping are custom designed each time to provide the most economical solution.

What if I have a hot stack?

In the case where the stack shell is hot, > 180° F (80° C), some special precautions must be taken. The Damper will be designed so that there is a gap between the shell and the damper, to essentially break the thermal bridge. We do not want the damper to exceed the boiling point of water, which would cause the damper to experience internal pressure. By breaking the thermal bridges we ensure that the temperature will stay below the boiling point.