Piggy-Back Stacks

We often get the question of how to model a Tandem or Piggy back stack in MecaStack. One can be handled by the software and the other cannot.

Piggy-Back Stacks:

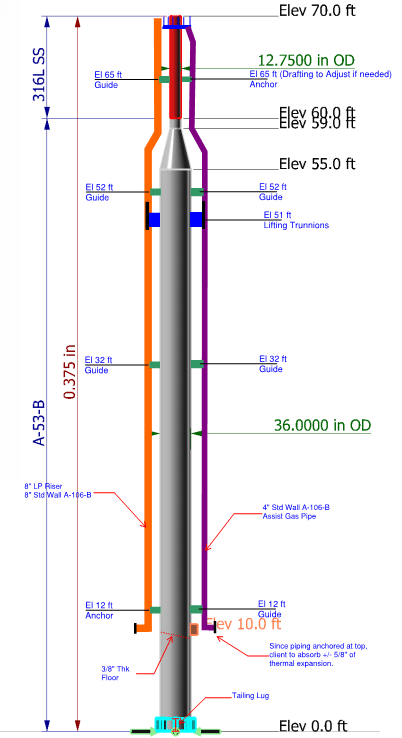

A Piggy-Back stack is one where one or more stack is supported by another stack. Usually the biggest stack is the main support, and then you have smaller stacks or piping attached to the side of the main stack. The main stack resists all of the weight and lateral loads of the piggy-back stack(s). MecaStack can handle this type of design, as long as the Piggy-Backs are not too large. These are handled by adding the piggy-back risers as either “Piping” or “General Attachment”. Please note that MecaStack doesn’t consider any of the eccentricity due to the piggy-back riser being eccentric to the centerline of the stack. If this effect is expected to be large, then this approximate method in MecaStack may not be suitable; however, in most cases this eccentricity is minor, and so it can be ignored.

Note: Usually due to differential thermal expansion between the main and piggy-back risers, the two risers need to be able to move independently vertically. Usually the piggy-back riser is anchored at the bottom, and then guided to the top to allow it to expand/contract freely.

Tandem Stacks:

Note: Similar to a Piggy-back riser, the tandem risers are normally guided so that they can move independently in the vertical direction. This is important for differential thermal expansion; however, it is also important because the two risers are working together, and anchoring the two together could place extremely large vertical reactions on the interconnecting structural members.