Steel Stack Deflection

When designing a stack should steel stack deflection be a concern? It’s a good question and one that comes up frequently, The design standards give some guidance, but the standards vary in how they handle steel stack deflection and there is some room for interpretation. Here we discuss the major considerations with regard to stack deflection.

Steel Stack Deflection due to Along and Across Wind?

When we refer to steel stack deflection, we are referring to the lateral deflection of a stack due to loads (wind, seismic, vortex shedding, etc.). Most stacks are controlled by wind loading, unless the stack is very heavy and in a high seismic zone, in which case it might be controlled by seismic loading. For the purpose of this discussion lets assume we are dealing with a typical stack that is being controlled by wind loading. There are two types of wind loading, along and across wind loading. Along wind loading is considering the stack deflection due to the maximum design wind loading, in which case the stack deflection occurs “along” the direction of the wind load. For example, if a stack is in the Texas Gulf coast and is designed for a 140 mph [62.5 m/s] hurricane wind load, then there will be stack deflection due to that wind that will be along the wind direction. Although we don’t want the deflection to be excessive, it stands to reason that if a stack is in the middle of a hurricane that there are probably not many people paying attention to the amount of stack deflection since they have more important concerns. We don’t want the stack deflection to compromise the structural integrity, but we are probably less concerned with the exact amount of the deflection.

Another form of steel stack deflection due to wind is that due to wind induced vibration, or vortex shedding. We refer to this as “across” wind loading, since the stack deflection occurs in a direction perpendicular to the direction of the wind. For example, if a wind is blowing North to South, generally the stack deflection is West and East, or across the direction of the wind. For our stack mentioned previously that has a design wind speed of 140 mph [62.5 m/s] it might have a critical wind speed that is much lower, let’s say it is 30 mph [13.4 m/s]. The critical wind speed is the wind speed at which resonance can occur for the stack. In other words, in our example if the stack experiences sustained wind speeds at the critical wind speed of 30 mph [13.4 m/s] then it is possible that vibration can occur. Since the vibration can occur at a low wind speed then it can occur much more frequently than the hurricane winds, and so it is much more likely that it can be observed by personnel. In this case we are concerned with the structural integrity, but we are also concerned with the “perception” to the public that there is a problem. If an observer sees a stack deflection, which is large enough that they can see it occuring at a moderate wind load, then they often become alarmed and perceive the stack as being structurally unstable. Steel stack deflection due to across wind loading (vortex shedding) has the greatest potential for being noticed and causing concern with observers.

When does Stack Deflection Compromise Structural Integrity?

There are some issues related to structural integrity that should be considered when evaluating stack deflection:

Refractory/Internal Components:

There are many company specifications that limit stack deflection to the height/200 [6 inches per 100 ft] of towers that have refractory lining or internals that could be damaged with excessive stack deflection. Most stacks do not have internals (trays, etc.), but there are some stacks with castable refractory lining. We believe that a limit of height/200 is conservative for a stack with refractory, we have seen examples of stacks that have had greater deflection with no damage to the refractory. The refractory is important for the structural integrity of the stack, because if it is damaged then the steel shell can be exposed to excessive temperatures and/or corrosion.

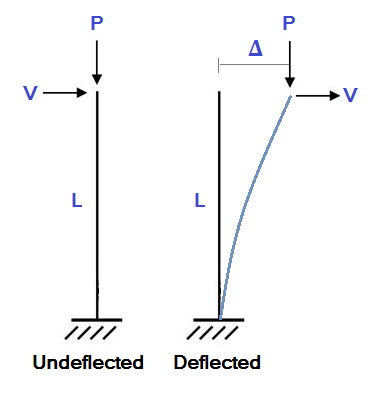

P-Delta Effect:

There is an effect referred to as the P-Delta effect. This is a situation where your deflection is so large that the weight of the structure introduces a secondary moment due to it being eccentric to the centerline of the stack. This is illustrated in the corresponding diagram. The vertical load ‘P’ is eccentric to the center line of the structure by ‘Delta’, so that the secondary moment is introduced which is P x Delta. ASME STS-1-2016 recommends that P-Delta be considered when the deflection exceeds Height / 100 [12 inch per 100 ft]. MecaStack does consider the P-Delta effect when the non-linear option is selected for the analysis.

What if its a Guy Wire Supported Stack?

Guy wire supported stacks are very flexible, which is typically why there are guy wires in the first place. In the case of a guyed stack, attempting to use a low deflection limit can be very problematic. Stacks are often designed to relieve hot gases, and these hot gases cause the stack to thermally expand. When guy wires are present, this thermal expansion is resisted by the guy wires. If we impose a low deflection limit, then the guy wires need to be stiff in order to achieve that low limit. A stiff guy wire will impose larger forces on the stack, guy wires, and foundation when they are resisting thermal expansion of the stack. It becomes a never ending circle, like a dog chasing it’s tail. Meca typically recommends that if a deflection limit is imposed on a guy wire supported stack, that the deflection be no less than the height/100 [12 inches per 100 ft], especially if the stack design temperature is 300 °F [149 °C] or greater.

Note: MecaStack automatically performs a non-linear analysis when guy wires are present because the guy wires are non-linear. This non-linear analysis takes into consideration the P-Delta effect automatically.

What do the Design Codes Require?

The design codes for steel stacks vary on how they handle steel stack deflection, here are what some of the most common steel stack codes require:

ASME STS-1-2016:

When the deflection exceeds height/100 [12 inches per 100 ft] then a P-Delta analysis is to be considered. The max deflection should be calculated with the foundation rotation or movement being considered. The max deflection shall also be considered when evaluating clearance with equipment and structures near the stack.

CICIND Steel Chimneys 2010:

The secondary effect (P-Delta) shall be taken into consideration when Beta > 0.6, where:

Beta = h * (N/E*I)^0.5

h = Height in meters

N = Total Axial Load at base of shell in Newtons

E*I = Stiffness of cross section at base of chimney (N*m^2)

As long as the stress is acceptable then there is no limit on the stack deflection; however, so as not to alarm bystandards the stack deflection shall be limited for vortex shedding to 10% of the top diameter for critical chimneys and 25% of the top diameter for normal chimneys (ref Appendix 3).

British BS 4076:

When the chimney carries weight other than it’s self weight, such as a heavy lining, guy wire loads or other imposed loads, then the P-Delta effects should be considered. The P-Delta should be considered when the total axial stress is greater than 1/3 of the bending stress due to wind.

Indian IS 6533 Part 2: 1989:

The maximum deflection at the top of the steel chimney produced by the wind load without taking into account the dynamic factors shall not be greater than the unsupported height/200.

Eurocode EN 1993-3-2:2006:

The maximum deflection due to along wind loading is limited to the height/50. The maximum stack deflection due to across wind (vortex shedding) is limited to the following:

Reliability 3 (Strategic Location) 5% of Top Outer Diameter

Reliability 2 (Normal Location) 10% of Top Outer Diameter

Reliability 1 (Open Countryside) 15% of Top Outer Diameter

Conclusion:

We recommend first following any of the guidance dictated by the code being used for the design. Since many of these give limited deflection requirements, Meca typically recommends the following steel stack deflection limits as a general guideline:

Along Wind/Seismic Loading:

Self Supported Stack: Height/133 [9 inches per 100 ft]

Guy Wire Supported: Height/100 [12 inches per 100 ft]

Across Wind (Vortex Shedding) Loading:

5% of Top Outer Diameter

In my experience, if you tell a client that you are supplying a stack that is designed with no deflection limit, they view this as a “cheap” design. They then insist that it’s too liberal to use no limit, so if they apply any limit it is typically the limit of height/200, which is often applied to many structures and pressure vessels. This can unnecessarily add cost to the stack, especially if the stack is tall and slender. This is why we recommend rather than designing to no limit, you use the limits stated above. They are reasonable limits that will minimize the concern for P-Delta, but also not impose a huge cost increase for little gain.

In the case of across wind vibration, nobody wants to design a stack that observers can see vibrating. You can explain all day long that it is acceptable and the numbers prove it, but there are a certain percentage of persons that will just always view it as unsafe. To avoid this situation, we try to limit the across wind amplitude to a minimal amount when at all possible.