Ultimate Guide to Material Properties

MecaStack has a built in database for stack material properties, which are intended to help the designer. There are some common questions and problems that we see when it comes to the use of the stack material properties.

Material Properties are NOT Automatically Updated:

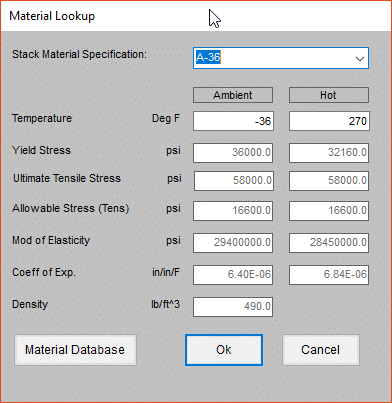

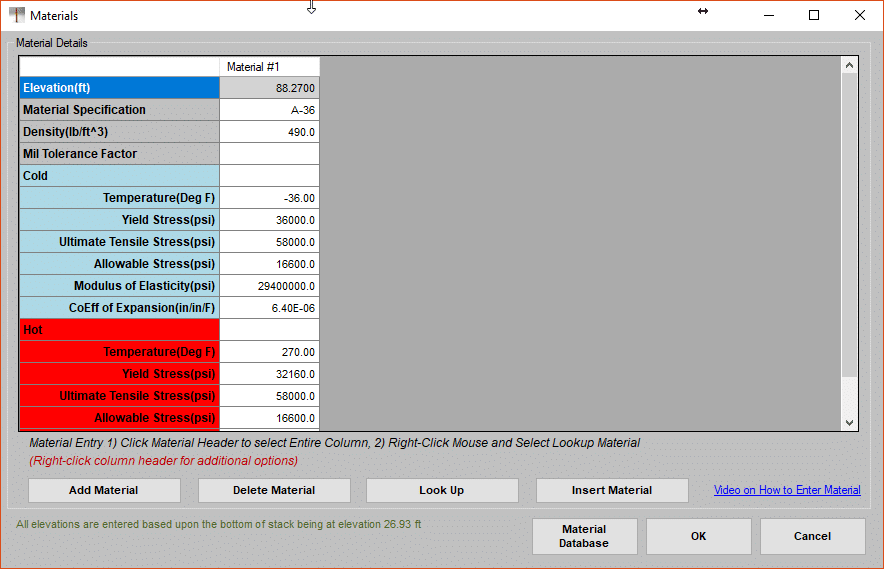

The first step when adding a material to your MecaStack model is to go to the Geometry > Materials selection. In the Materials menu select the “Look Up” option. When a material is selected, a change in the temperature value cells will result in a change for the stack material properties.

Once OK is clicked on the lookup, a SNAPSHOT of these stack material properties are moved to the material form. These are a snapshot, meaning that the values are just the values at the selection of the material and they are no longer linked to the database. If you change the temperature or material on this screen, the properties will NOT be updated. You must go back into the “Look Up” form in order to update the properties.

Why aren’t the properties automatically updated? There are a couple of reasons. Our database doesn’t include every possible material. Sometimes you use a material that is similar to the material you need, and so you use them and then modify the material description. Another reason might be that you don’t want to use the properties exactly as they are imported from the database and this gives you the ability to override those values.

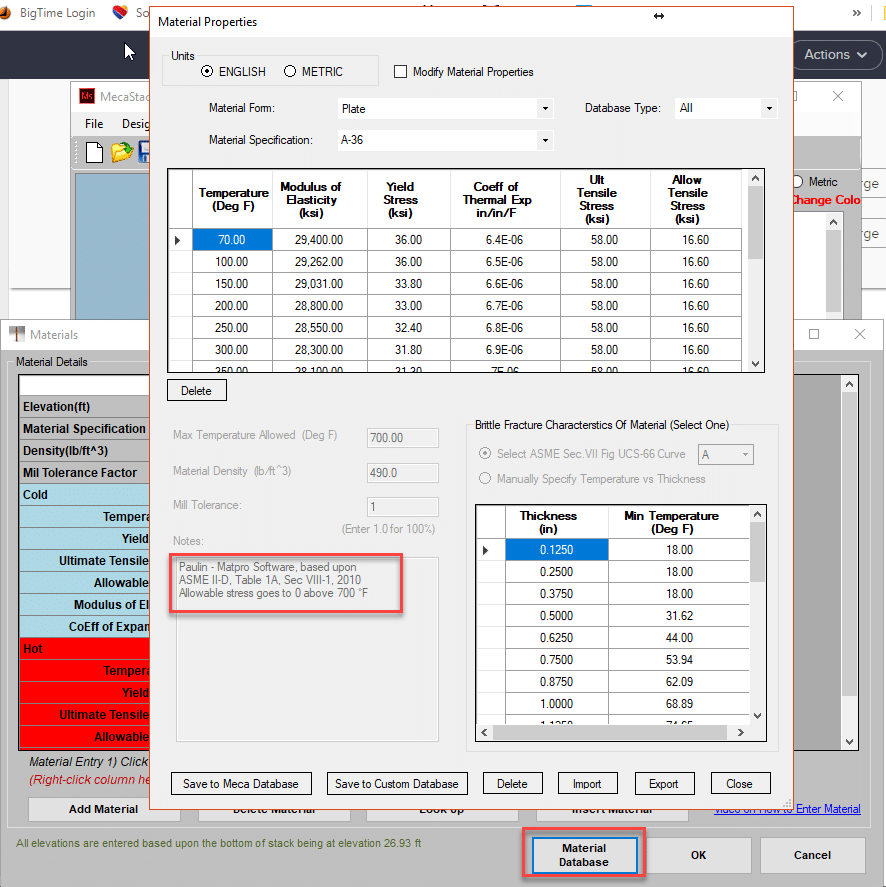

What is the Origin for the Stack Material Properties Data: