I Feel the Need, the Need for Speed

In my humble opinion, the Movie Top Gun is one of the best movies of all time. One of the best parts is when Tom Cruise says “I feel the need, the need for speed”. It’s not just a great line, it also applies to many stack designs. More speed (critical wind speed) is exactly what we need in many instances to allow us to avoid the need for a damper or helical strakes.

Do we always need speed?

We calculate critical wind speed (Vc) for a stack, and this is the wind speed at which the stack can experience wind induced vibration. The stack design codes provide an upper limit and when the critical wind speed is above this limit, then we no longer have to consider vortex shedding. The basic logic is that if the Vc is higher than any wind speed we expect to ever see on the stack, then it’s only logical that we can assume that vortex shedding will never occur.

For example, I’m located in Broken Arrow, Oklahoma, and here the design wind speed per ASCE 7-16 for Category II structures is 110 mph. I decide to design a steel stack for my back yard just to irritate my neighbors, and this stack happens to have a critical wind speed of 180 mph. That means at 180 mph the stack could experience vortex shedding; however, this is much higher than 110 mph for my region, and so it’s highly unlikely that my stack will ever see 180 mph in it’s life. Therefore, it’s not necessary that I even consider vortex shedding. The actual numbers we compare for with the upper limit aren’t quite this simplistic, but that is the basic concept.

When can we use more speed?

We can use this concept to our advantage in certain situations. Now if your critical wind speed is 25 mph and your design wind speed is 100 mph, then this concept isn’t going to help you. The additional steel necessary to increase your critical wind speed from 25 mph to well above 100 mph is enormous. Where this concept comes into play is when your critical wind speed is maybe 5% to 10% less than the upper limit.

Another time we could use more speed is if we have problems with higher modes. Your mode 1 critical wind speed may only be 20 mph; however, your mode 2 critical wind speed might be just below your upper limit. In this case you could increase the stiffness of the stack and raise mode 2 above the upper limit, and then you only have to address mode 1.

How do we increase the Critical Wind Speed?

From a dynamic standpoint, we can reduce our complicated stack into the simplified system shown to the right, with a beam of stiffness “K” and a mass “M” at the top. Visualize hitting the mass with a big hammer, the mass will start oscillating from side to side. We can also calculate the frequency of oscillation with the “K” and “M” values. The critical wind speed (Vc) is directly proportional to the frequency. The math is simple:

f = (K / M)^0.5

Vc = f * D / S

D = Average Outer Diameter of Top 1/3 of stack

S = Strouhal number which is usually 0.2

We can see from this simple equation that to increase Vc, we simply need to either increase D or increase f. We can increase f by either increasing stiffness (K) or decreasing mass (M). This gives us several options to increase Vc.

1) Increase the outer diameter of the top 1/3 of the stack.

2) Increase the frequency of the stack, which can be done multiple ways:

a) Decrease the mass, and most importantly the mass near the top. This isn’t always a feasible option, but if it’s possible to reduce the mass near the top it can help increase the frequency.

b) Increase the diameter of the stack, which will increase the stiffness (K). For the biggest impact, increases in diameter at the base of the stack will have a far bigger impact on the frequency than changes in diameter at the top.

c) Increase the thickness of the stack, which will increase the stiffness (K). For the biggest impact, increases in the thickness at the base of the stack will have far more impact on the frequency than changes in the thickness at the top (which also increases mass, and lowers the frequency).

Critical Wind Speed Example:

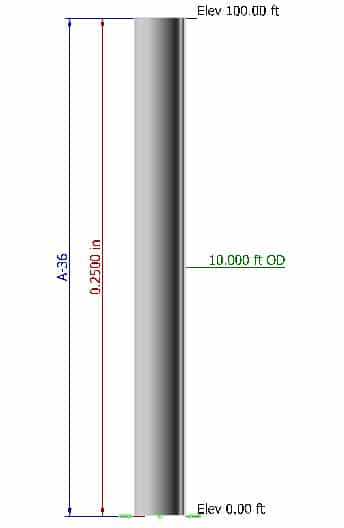

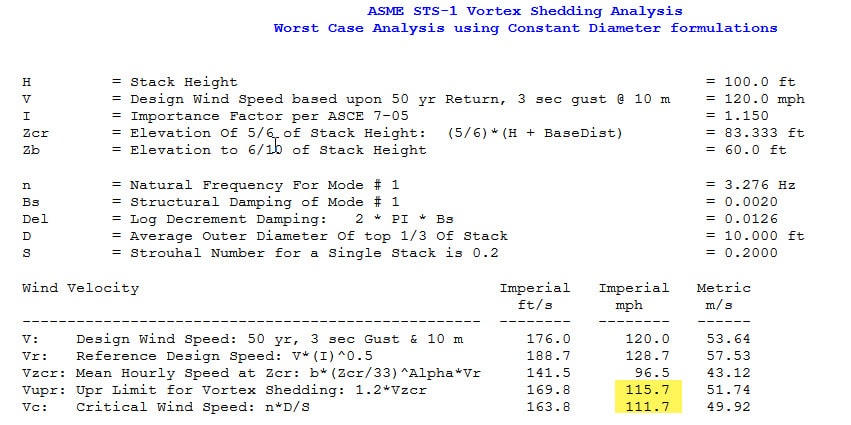

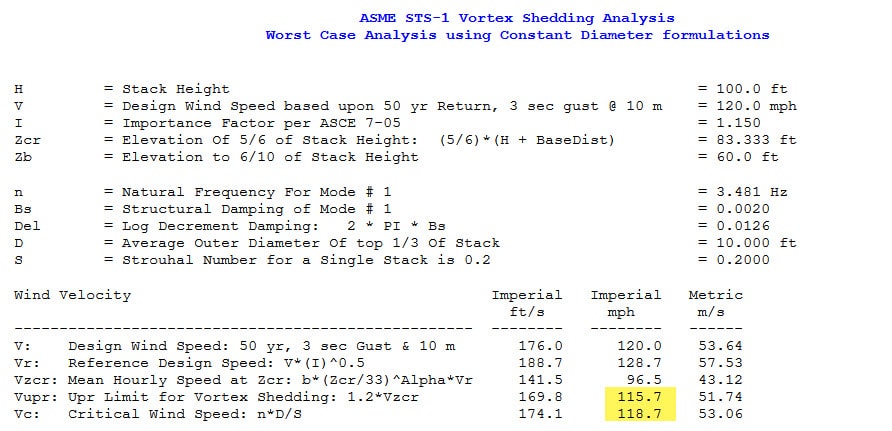

To illustrate this trick lets use a real example. If we have a stack that is 100 ft [30.48 m] tall, 10 ft [3.048 m] OD and 0.25 in [6.35 mm] thick, then MecaStack will give a natural frequency of 3.3 Hz. This corresponds to a critical wind speed of 111.7 mph. The upper limit for vortex shedding is 115.7 mph. This means that if we can increase the Vc from 111.7 mph to something greater than 115.7 mph then we will no longer need to consider vortex shedding.

The easiest way to increase Vc is to increase the stiffness. This can be done by making the stack lighter, or making it more rigid. We can have the biggest impact by increasing the diameter, but increasing thickness can also have an impact. Generally changes at the bottom of the stack have a bigger impact than changes at the top of the stack.

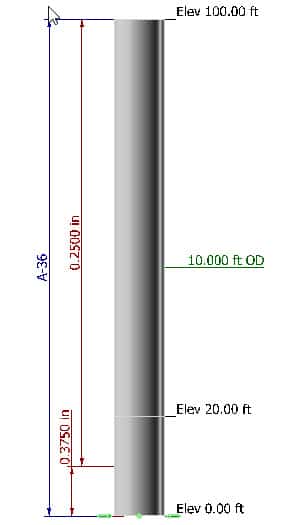

How do we revise the stack?

Let’s just make a simple change of increasing the bottom 10 ft [3.048 m] from 0.25 in [6.35 mm] to 0.375 in [9.5 mm]. These results are shown below, and we are able to increase Vc > Vupr, eliminating the need to check vortex shedding. This change would generally be far less expensive than adding a damping solution or adding helical strakes, and it’s far simpler.

Conclusion:

Increasing speed isn’t going to work in all instances, but there are many instances where this approach will work and save you time and money. The size and stiffness of stacks vary widely, and so the amount of additional steel needed to raise Vc above Vupr will vary widely. Sometimes just adding a small amount of steel can get you out of the danger zone, and other times it can take a tremendous amount of steel just to raise the Vc by 0.5 mph [0.2 m/s]. You just have to try and see if it will work on your stack.

If we can be of assistance, please don’t hesitate to contact us at [email protected]