Add Some Guy Wires

When and why should I use guy wires on a stack? When a stack has a vortex shedding problem there can be many factors that determine which solutions are the best. Guy wires aren’t always the most conventional solution, but its always an option to consider.

How do Guy Wires Help?

By adding guy wires we can reduce the likelihood of vortex shedding by a couple of different methods:

1) A guy wire supported stack has a recommended structural damping of 0.006. Depending upon the stack, a self supported stack could have structural damping of only 0.002, and so adding guy wires can triple that value. Often this alone is enough to solve the problem.

2) The addition of guy wires increases the stiffness, and this will change the frequency and the critical wind speed.

3) Guy wires can help resist the lateral loads due to vortex shedding, bringing the stresses to an acceptable level.

Example:

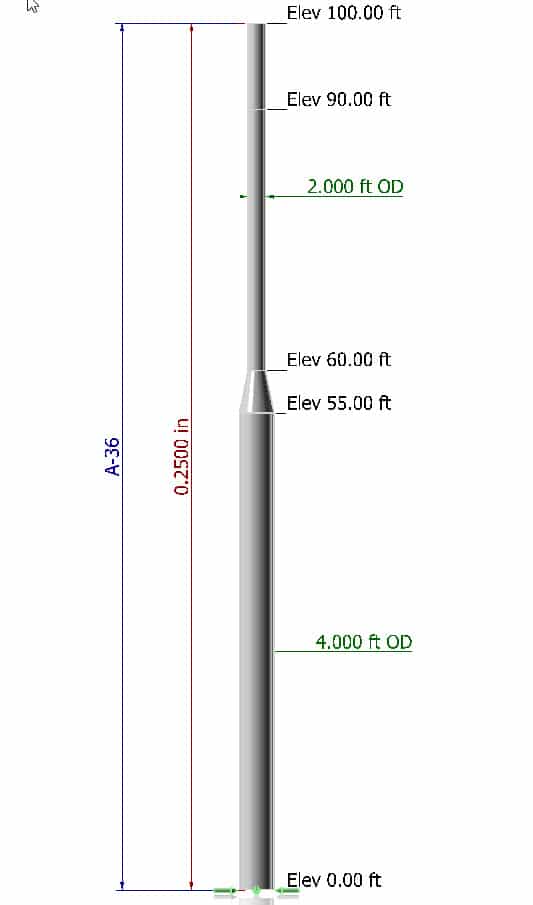

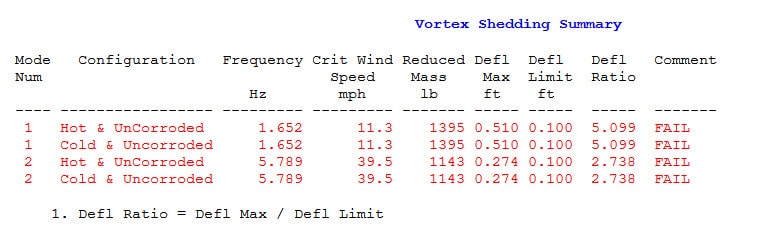

To illustrate this technique of lowering the Vc, lets use a real example. If we have a stack that is 100 ft [30.48 m] tall, 2 ft [0.6 m] OD at the top and then transitions to 4 ft [1.2 m] OD at the bottom. The entire stack is 0.25 in [6.35 mm] thick. Using the MecaStack software, we get the following dynamic results

Mode # Freq (Hz) Vc (mph) Vc (m/s)

1 1.6 11.3 5.1

2 5.8 39.5 17.7

Both modes show that there are high amplitude vibrations due to vortex shedding.

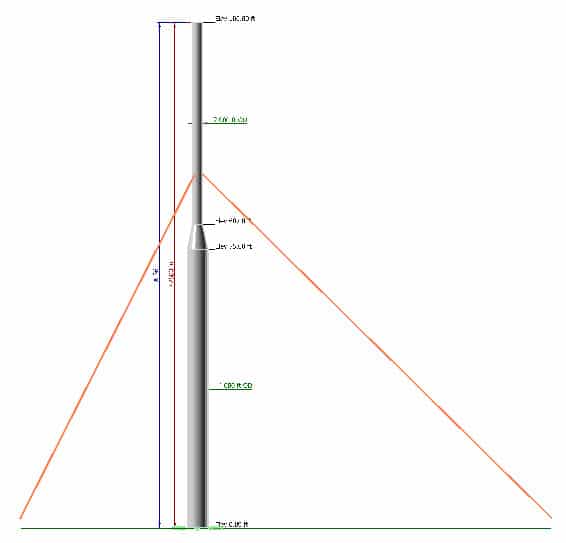

Add Guys:

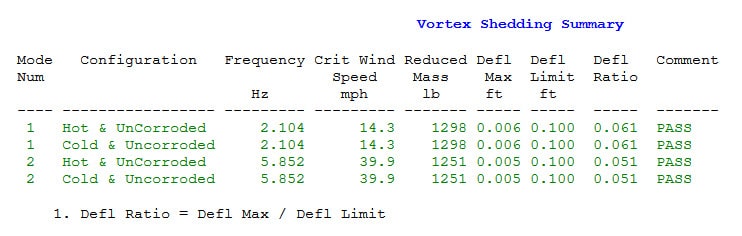

Now lets look at the same stack after adding 1/2″ [12 mm] diameter wire rope guy wires. By adding these guy wires we do the following:

* Increase Structural Damping from 0.002 to 0.006

* Increase the frequency

* Increase the lateral resistance to loads

All of these combined resolves our vortex shedding problems for mode 1 and mode 2. The results are shown below, and the stack is now passing both modes.

Confession from a Guy:

I have a confession to make, I don’t completely trust the calculations that predict vortex shedding on guy wire supported stacks. The Euro standards do the most detailed job of giving guidance in this area, but most of the other codes don’t give much guidance at all. As a result, most of the stack codes in MecaStack just analyze a guyed stack the same way we would analyze a self supported stack; however, taking into consideration the increased structural damping and stiffness provided by the guy wires. The good news is that there have been very few instances where guyed stacks actually vibrate, and even in the rare cases where I have personally been involved, the calculations still indicated that there was no problem. The best advise that I can offer is to avoid the situations which I have seen that led to wind induced vibration:

1) Top guy wire too far down from top of the stack. I try to keep the top guy wire as close as reasonably possible to the top of the stack, usually a few feet or couple of meters.

2) Structural bridge strand was used in all cases where I have witnessed vibration. I think it is very stiff and provides little damping. Bridge strand can be used, but the combination of a guy wire that is far from the top and the use of bridge strand is a dangerous combination.

Our MecaStack software does consider vortex shedding, but since the codes don’t do a great job at addressing this for guy wire supported stacks you should apply good engineering judgement.

Big Stack –> Big Guys:

If you have a big stack, then you are going to need big guy wires. There might be a tendency to think that the stack is already strong, so it just needs a little help from the guy wires. I think of it this way, imagine attaching guy wires to a mountain to provide support. If you attach a small diameter guy wire to the moutain, do we really expect the guy wire to take any of the lateral load? You would need a VERY big guy wire to compete with the high stiffness of the mountain, otherwise all lateral loads would just go to the mountain. The same is true of stacks, Big Stacks require Big Guy Wires.

Conclusion:

Adding guy wires to a stack to address vortex shedding isn’t very common, but it is often a valid solution. I’ve only personally seen this done a couple of times in my career. Usually a stack is self supported (free standing) for a reason, because there isn’t enough space for guy wires; however, when there is space for guy wires, it is a possible solution.