How to Determine Damping

We can all grasp the physical attributes of a stack such as the height, weight, diameters, etc.; however, what is the stack’s structural damping? Does MecaStack estimate the damping of the stack? Is there any harm in just arbitrarily changing the damping value?

Damping Basics:

To answer this question we first need to cover some basics. If a structure vibrates and has no damping, then we would have the blue Undamped curve to the right. The amplitude is the same for each cycle and continues indefinitely. If our structure is Critically Damped, then we have the green curve where the vibration almost immediately attenuates and goes to zero.

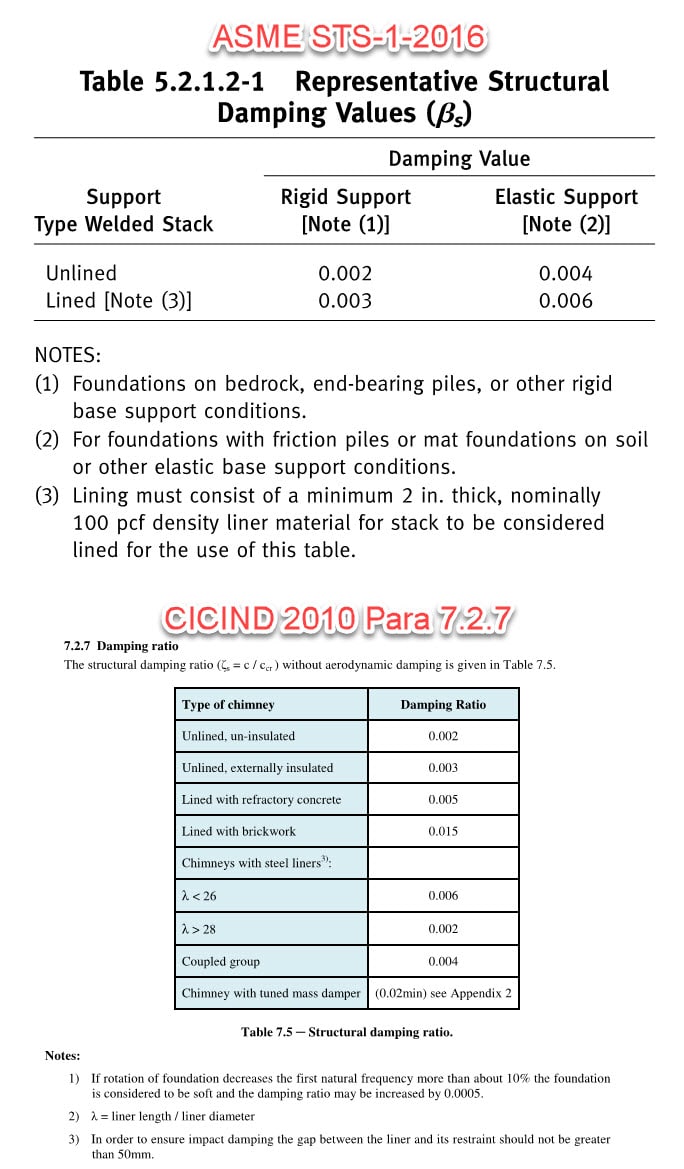

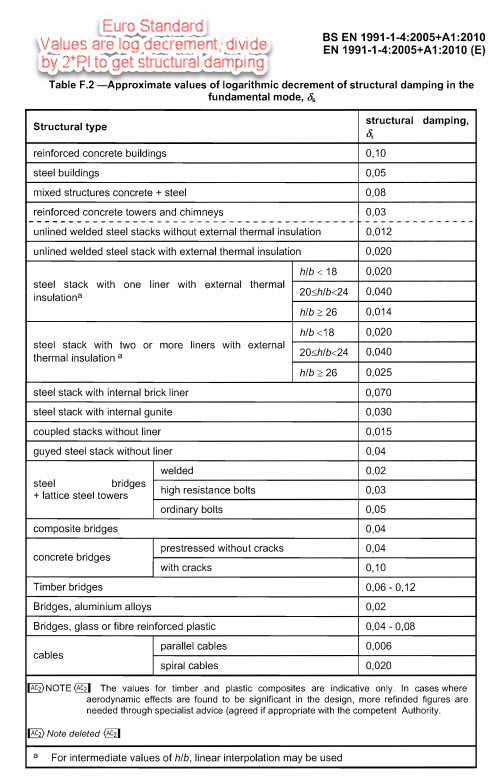

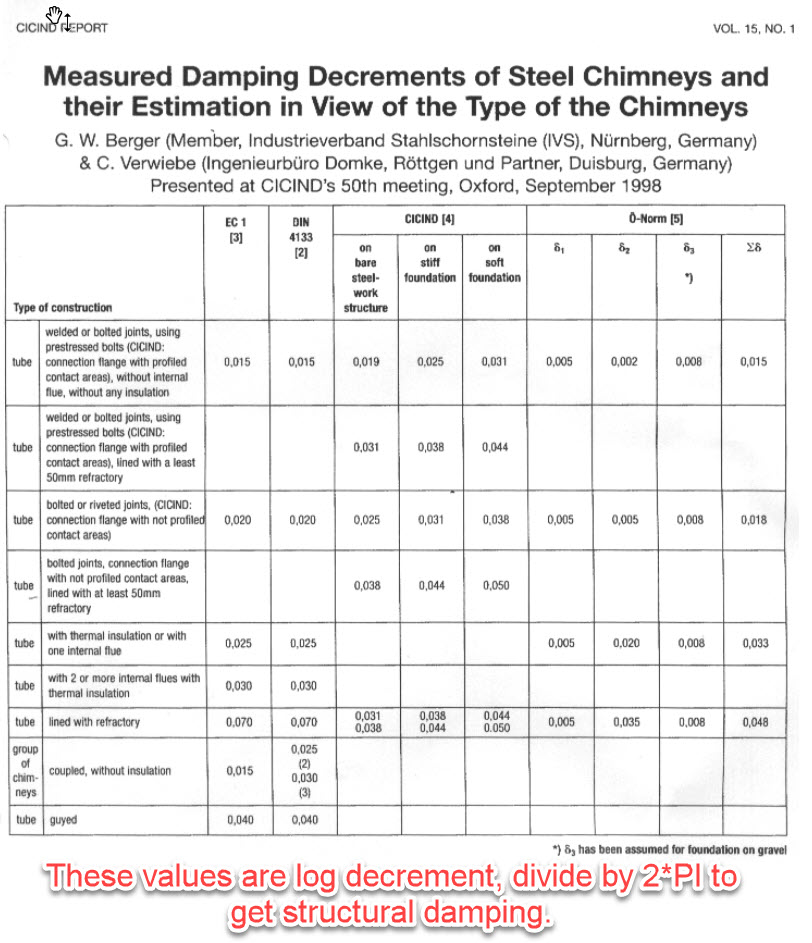

The structure damping represents the structures inherent ability to absorb energy. There are many factors that contribute to the damping:

- Foundation and Soil (A soft soil/foundation system absorbs energy and a very stiff soil/foundation system doesn’t).

- Construction of the stack (Bolted connections increase damping, welded decrease damping)

- Lining inside the Stack (If stack has a substantial insulation/refractory/liner then it will increase damping).

- Internal Liner or Dual Wall Stack (Higher damping).

- Guy Wires

- Attachments to the stack (Piping, Ladders, etc..).

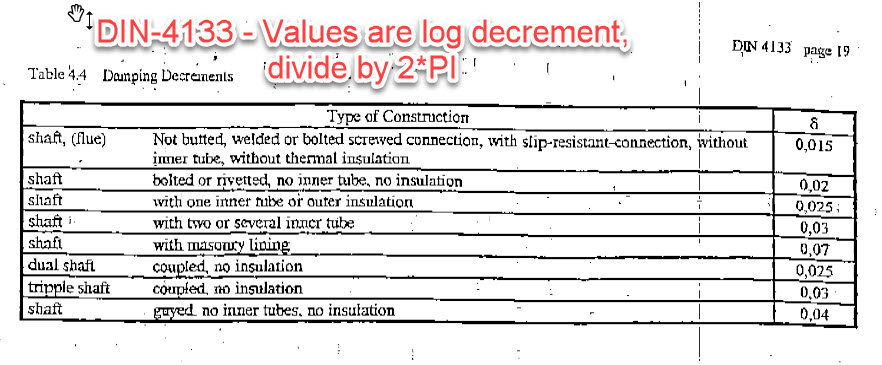

How do I quantify my value?

This is the difficult part, how do you put a number to all of these factors. The stack codes provide some guidance, but much of this is subjective. If you are too liberal, you run the risk of your stack having a major problem. If you are too conservative, you increase your cost and hurt your companies profitability. I can’t give you the answer, you will have to do a risk-benefit analysis to determine the right answer; however, I can give you some resources below to help you arrive at the right answer for your situation.

Does MecaStack estimate Structural Damping?

No! The software can not and will not estimate damping. It will assign a value based upon your selections (Elastic vs Rigid foundation, Lined vs unlined, etc..), but at the end of the day it is the stack designers responsibility to make sure the value is appropriate. This parameter is very important and shouldn’t be taken lightly. Just increasing the damping by 0.001 could make a huge impact to the results, so the designer needs to understand when it is justified to use higher values.

What about Aerodynamic Damping?

This whole article is focused on structural damping. There is another type of damping called “Aerodynamic Damping”; however, the aerodynamic damping is only beneficial for Along Wind loads, it can not be considered for Across Wind Loads (vortex shedding); therefore, we will not cover it in this article.

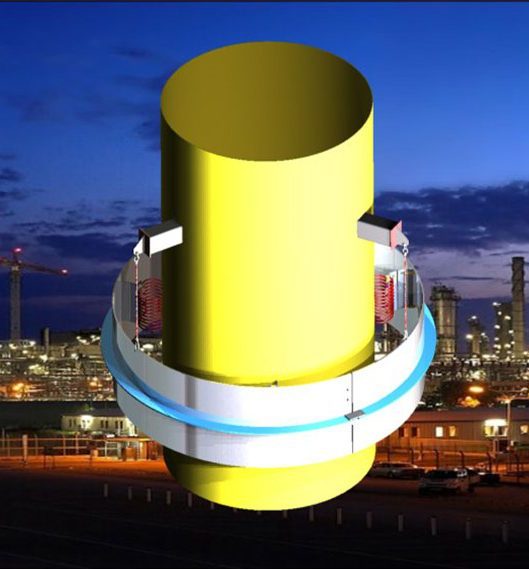

What if I have a Damper?

If you have a damper, such as a Damping Pad or Tuned Mass Damper (TMD), then estimating the damping becomes easy. The damper supplier will give you the estimated damping for your structure. You can then enter this value into MecaStack and perform your analysis to confirm that everything is working. If you use Meca for your damping needs, we ask for the MecaStack input file (*.stk) to be sent to us, and then we will return the file with the appropriate damping parameters as well as damper info (weight, dim’s, etc.) entered into your file.

Conclusion:

The estimation of structural damping is an in-exact science. To really know the damping you would have to build the stack, erect it, and then do measurements on the stack to measure the damping. This is obviously not feasible, and so we make conservative assumptions based upon the resources we have available (see recommended damping values above). When in doubt, my recommendation is to guess a lower value to be conservative, because the last thing any stack designer wants is to find out their stack is vibrating.