Slow Down

I’ll bet “Slow Down” isn’t an expression you hear much in your business. I dream of a day when a customer tells me, “Slow down, we really don’t care when you finish your design.” I can’t get you more time on your deadline, but I can tell you one instance that slowing down will actually make your customer happy.

When is Slowing Down good?

We calculate critical wind speed (Vc) for a stack, and this is the wind speed at which the stack can experience wind induced vibration. The stack design codes provide an upper limit, and when the critical wind speed is above this limit then we no longer have to consider vortex shedding. Unfortunately there is no corresponding lower limit for critical wind speed, where below this limit we would be able to ignore vortex shedding; however, practically there usually is a lower limit where below that point vortex shedding loads become negligible. I’ll refer to this as a “Virtual Lower Limit” (VLL).

What is this Magical VLL?

Early in my career we used a rule of thumb that indicated if the critical wind speed (Vc) was less than 15 mph [6.7 m/s] then the energy in the wind was small, and we could ignore vortex shedding. Although this rule of thumb served us well for many years, it isn’t always correct; however, in many cases it is a good target for a VLL. The actual value may be higher or lower on your particular stack, but on average I think 15 mph [6.7 m/s] is a good initial guess.

How do I calculate the VLL?

I don’t have an equation used to calcualte this value, but it’s a trial and error solution. I use our software, MecaStack, and I make changes to my stack to lower the critical wind speed (Vc) and then I try to find the point at which the vortex shedding deflection and loads are negligible.

How do we decrease the Critical Wind Speed?

From a dynamic standpoint, we can reduce our complicated stack into the simplified system as shown, with a beam of stiffness “K” and a mass “M” at the top. Visualize hitting the mass with a big hammer. The mass will start oscillating from side to side. We can also calculate the frequency of oscillation with the “K” and “M” values. The critical wind speed (Vc) is directly proportional to the frequency. The math is simple:

f = (K / M)^0.5

Vc = f * D / S

D = Average Outer Diameter of Top 1/3 of stack

S = Strouhal number which is usually 0.2

We can see from this simple equation that to decrease Vc, we simply need to either decrease D or decrease f. We can decrease f by either decreasing stiffness (K) or increasing mass (M). This gives us several options to decrease Vc.

1) Decrease the outer diameter of the top 1/3 of the stack.

2) Decrease the frequency of the stack, which can be done multiple ways:

a) Increase the mass, and most importantly the mass near the top. Sometimes this is as simple as increasing the thickness on the cylinders near the top and/or adding some other mass to the top of the stack. Changes to the top have the biggest impact to the frequency.

b) Decrease the diameter of the stack, which will decrease the stiffness (K). For the biggest impact, decreases in the diameter at the base of the stack will have a far bigger impact on the frequency than changes in the diameter at the top.

c) Decrease the thickness of the stack, which will decrease the stiffness (K). For the biggest impact, decreases in the thickness at the base of the stack will have far more impact on the frequency than changes in the thickness at the top (which also decreases mass, and increases the frequency).

Example:

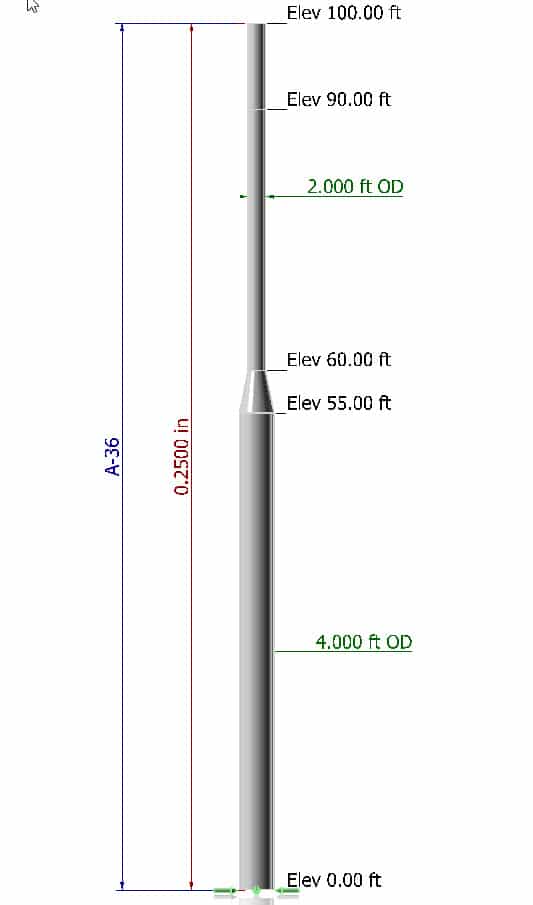

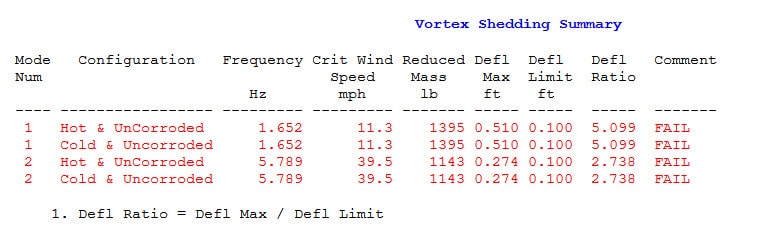

To illustrate this technique of lowering the Vc, lets use a real example. If we have a stack that is 100 ft [30.48 m] tall, 2 ft [0.6 m] OD at the top and then transitions to 4 ft [1.2 m] OD at the bottom. The entire stack is 0.25 in [6.35 mm] thick. Using the MecaStack software, we get the following dynamic results

Mode # Freq (Hz) Vc (mph) Vc (m/s)

1 1.6 11.3 5.1

2 5.8 39.5 17.7

Both modes show that there are high amplitude vibrations due to vortex shedding. Even though mode 1 is already less than our previous VLL of 15 mph [6.7 m/s] that was previously mentioned (I also mentioned previously that this is not an absolute limit but rather just a rule of thumb).

Lower Stack Vc:

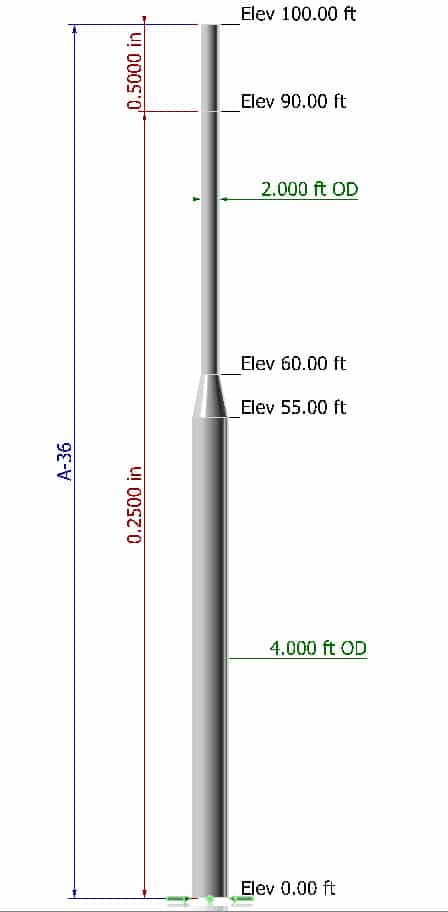

Now lets make a change to the stack so that the Vc is lowered. To do this we want to lower the frequency, which in turn will lower the Vc. We do this by changing the top 10 ft [3.04 m] of the stack from 0.25 in [6.35 mm] to 0.5 in [12 mm]. This additional mass at the top of the stack will lower the natural frequency of the stack, which in turn will lower the Vc.

Mode # Freq (Hz) Vc (mph) Vc (m/s)

1 1.4 9.6 4.3

2 5.3 35.9 16.0

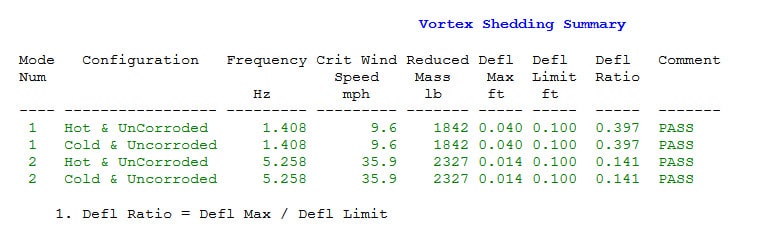

The first mode Vc has been lowered to 9.6 mph, but we also ended up lowering the mode 2 Vc to 35.9 mph. This is an unavoidable consequence, when you lower the frequency for one mode you are going to lower the critical wind speed for all modes; however, we got fortunate in this stack in that we changed the dynamic behavior for mode 1 and mode 2 benefited also. The mode 2 critical wind speed decreased, which in this case isn’t necessarily a positive thing, but the mass distribution and frequency changed and now the deflection estimate is much lower for vortex shedding for mode 2. This won’t always be the case, it’s just something you have to evaluate by trial & error to determine the net result on a specific stack.

Conclusion:

This can be a complicated problem to solve. You can add mass to the top, and lower the critical wind speed for mode 1; however, you also will lower the mode 2 critical wind speed also, and sometimes this can make mode 2 better and other times it will make it worse. You could end up being like a dog chasing its tail. Sometimes the design comes together easily, and other times you just go in circles.

This technique of lowering the critical wind speed is worth investigating when you find that your mode 1 critical wind speed is low and in the range of 15 mph [6.7 m/s]; however,it can be tricky and sometimes there is not a valid solution. Please feel free to contact us if you need help or advice at [email protected]